At the beginning, when in my house we decided to purchase this kitchen food processor/blender almost 10 years ago, I considered it to be somewhat of an overpriced consumer asset in spite of the multiple features that it enclosed. Still I went with the hype and gave some credit to how much it could make life easier, in particular when it came to cooking meals and otherwise more complicated recipes.

But it was not before some experience with the device and the first caveats, that I could understand how much of a product fraud this device proved to be.

First, if one is to shell out around 1000 € for a blender, there are certain expectations that build up. Not that it would need to be gold plated or something, but the first experience was that it would be not much different from most kitchen appliances in respect to the plastic materials used, and the engineering and hardware required to fulfill its functions.

One aspect that early in the product live suggested a red flag, was the transparent measuring cup/cover: it started to crack, apparently due to the temperature stresses.

As the machine was still within its warranty period, we got a replacement for another cup. Both cups were identical (original and replacement) and had the >PC< plastic marking, which meant these were just made of polycarbonate plastic. These could be different grades though, and the later be more resistant that the original cup. However after some time (already after the warranty period), the new cup started showing the same effects.

The ultimate problem though, happened much later: in the past couple of months, the blender ceased to spin, issuing a "Er. 34" error on its display (it would briefly try to spin the motor, producing tone-like noises while doing so).

Upon opening the case and removing the motor, I could immediately tell that it was in pretty bad shape:

Even though it became this way much later than the 2 years warranty period, still we are talking about a 1000 € blender: in the way it is designed, the device largely depends on the endurance of the seals that exist in the bottom of the mixing bowl.

If these develop leaks, even though there are multiple channels to convey the flow of fluids to outside of the device, it is nearly unavoidable that some of it will eventually build up into the motor itself, and accumulate at the base of the motor, where these meet the bottom bearing of the later.

With continued exposure to the liquids and contaminants from the food, the motor parts will become damaged.

While the motor is of switched reluctance type, and as such (fortunately) it is difficult for electricity to come into contact with the fluids that eventually will ingress into the motor, still it is very susceptible to damage, as it is a cumulative process.

And from what I can tell this will happen very quickly once it sets in, because a year earlier I had to open the unit to repair another problem: a contact issue with the temperature selection buttons, and back then the motor was fine, and compared to the photos above, the motor was in much better condition. The photo below is from July 2019, and at present the motor is heavily rusted as is visible in the photos shown above.

Even though with some treatment the rust could eventually be removed, the major problem is the bottom bearing which in this case is seized.

These bearings are strongly attached to the motor shaft, probably with a very powerful thread-lock or epoxy.

The outer part of the bearing could be separated from the motor casing after applying some heath from a hot air gun, but regarding the inner part (which is in contact the motor shaft) I have gave up attempting to remove after several tries.

After seeing a video from another user, I realized that a more "serious" approach is required to remove this bearing:

https://youtu.be/MvfRbZT17kw?t=264

Currently I am pending between attempting to replace the bearings by removing the existing ones through some destructive process, or replace the motor altogether.

Again this is another aspect that suggests some level of deliberation regarding maintenance of this product: making it difficult to replace an otherwise simple part is probably in Vorwerk's best interest. A brand new motor will cost about 200€, which is a significant amount, considering the kitchen appliances (or respective parts) that could be purchased for this value: a modern washing machine for example will need to have a comparatively robust and sophisticated motor, and such part will normally cost a fraction of the price.

Besides the bearings (or motor), in the case there is the chance that more parts will need to be replaced: the root cause for the motor contamination is probably in the blade assembly and the bearing and seals that compose that part. Without it being replaced, probably the problem will occur again.

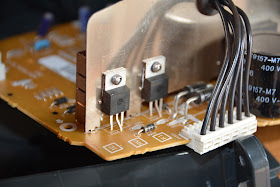

There is also the vague possibility that on the electronics side there can be damage as well. This is not such a likely scenario because Vorwerk seems to have given considerable thought to the motor control side, by implementing protections that likely prevent the IGBTs (the power transistors that drive the motor) from frying with much ease:

For those playing along at home, the particular type of IGBT used in the Thermomix TM31 is a SP04N60, and there are 6 of those in it. These are 600 Volt rated, and can deal with a maximum of 9.4 Amps in continued operation:

(https://datasheet.ciiva.com/12320/sgp-d04n60-rev2-2g5b15d-183889-12320112.pdf)

While a thorough reverse engineering of the board was not done, it is quite obvious that these IGBTs are being used in an H-Bridge configuration where each pair of IGBTs provides the push-pull configuration required to drive each of the 3 coil groups of the motor. There can be more complex configurations, but this is the simplest and eventually the cheapest, as it is the minimum size (transistor wise) H-Bridge possible to drive a switched reluctance motor.

I haven't yet tested the IGBTs as this would require each to be removed from the PCB, which is a laborious task, and it might only make sense to do so after the motor is fixed and an error or failure condition would still be present.

Another component that may require attention (although irrelevant in the case of a motor replacement), is the motor shaft sensor/encoder:

This board essentially implements a quadrature encoder (I've implemented one for a robot car I've built long ago - you can find more details here - https://www.creationfactory.co/2010/12/quadrature-encoder.html).

It has a couple of optical sensors separated such that a phase difference of 90 degrees in the signal from each sensor is obtained. This allows for direction and speed to be measured. A metal plate with multiple fins mounted in the top of the rotor functions as a spinning obstacle for the sensors, allowing the speed measurement to be obtained.

This quadrature encoder is essential for the operation of the motor, because it is the only source of feedback for the microcontroller. This allows the timing of the H-bridge switching to be correct against the current speed and position of the rotor. As with other types of brushless motors, while in theory it is possible to derive or estimate the position based on different methods that don't require a sensor, these tend to be challenging to implement and require complex signal processing and filtering in order to provide reliable results. That is because in that case the current flow in each phase must be measured and processed, or in other cases the back EMF of the unpowered phase sensed (not applicable in the case of the reluctance motor, at there is no magnetic rotor to influence it).

The only semiconductor present in the board is a quad schmitt trigger gate chip, and is responsible for performing some signal conditioning before the output is sent to the microcontroller:

This is rather simple electronics that shouldn't easily fail, in spite of the relatively harsh conditions in which this particular board is located. One aspect that caught my attention is the fact that the manufacturer didn't bother adding any conformal coating to this board. On the other hand, the main board where the power supply and control circuitry is located was properly covered with conformal coating in the back of the PCB. For example a view of the fully coated micro-controller present in this board:

I was able to read the writings in the package, and found:

NEC - JAPAN

PEDEU 3.80

1305MP211

Searching online, nothing can be found. Likely it is a standard NEC micro-controller that Vorwerk chose to have the package labels customized.

Still need to decide on what repair action to attempt. I have some reluctance (pun intended) in replacing the entire motor, even though this one is not in great condition overall..

Do you know what brand/type of conformal coating is that? I replaced a shorted igbt but now it has no protection and thus could be fried very soon. I'd like to use the same product not just a random coating

ReplyDeleteDo you know what brand/type of coating is that? I replaced a bad igbt but now it has no protection and thus could be fried very soon... i would like to be a pro and use the same conformal coating not just a random one

ReplyDeleteI am not exactly sure what kind of conformal coating they have used, but judging by the fact that has a somewhat rigid consistency and is this is a device that will be exposed to somewhat harsh conditions, it may be based on epoxy. If a silicon one was used, I would expect a more soft consistency, but again, I am not an expert in that field. I would say you can be on the safe side coating the area you repaired with epoxy, as it will protect the IGBT pins from moisture.

ReplyDeleteThank you very much for your kind reply and your nice blog post keep up the good work

ReplyDeleteThank you very much for your kind rely and your nice blog post, keep up the good work!

ReplyDeleteDo you know the correct coil winding configuration? Is it 3 coils 9.2 omhs each? 2 sets?

ReplyDeleteI have 4 coils measureable at 9.2 omhs and 2 coils measuring 18ohms. Possible open circuit in the coils?

Hello @Unknown,

ReplyDeleteIn my motor (in spite of it currently having seized bearings - but the coils are otherwise in good shape as far as I can tell), assuming the 6 pin connector facing you, with pins 1 through 6 from left to right, I could measure the following DC resistance:

* between pins 1 and 2 - Infinite

* between pins 1 and 3 - 9.59 Ohm

* between pins 1 and 4 - Infinite

* between pins 1 and 5 - 9.65 Ohm

* between pins 1 and 6 - Infinite

* between pins 2 and 3 - Infinite

* between pins 2 and 4 - 9.63 Ohm

* between pins 2 and 5 - Infinite

* between pins 2 and 6 - 9.65 Ohm

This seems to be in line with the measurements you have taken.

In this switched reluctance motor, it looks like the 8 coils are wired in two groups of 4 coils. These 4 coils are in turn arranged in series, where pins 1 and 2 constitute a center tap of each group of coils. As such:

* pins 1, 3 and 5 - group 1

* pins 2, 4 and 6 - group 2

The groups of coils are isolated from each other.

Hello,

ReplyDeleteHow did you remove the metalcovers and the upper plastic part without damages

Hi @Baschtler,

ReplyDeleteWell that was the hardest part. I used some heat from a hot air gun and carefully applied pressure to the single metal cover I was able to remove (with the help of a screw driver in order to separate the part from the rest of the motor). It required some persistence. The other one I gave up trying.

Hello,

ReplyDeleteIn my tm5 i have the erro C34 and the motor dont Spin well....the motor its clean dont have moister and its not seized bearing.

The error C34 its very common and i think its was a electrónic component that fail, i try every thing, cleaning the contacta... But i dont solve the problema...can you help me?

Hello @Tiago,

ReplyDeleteOne thing to check, assuming that the motor spins freely (no seized bearings and such), is to verify the optical shaft encoder. The motor power electronics are probably not affected (I think you should see a different error/behavior in that case).

Cheers

Hello, sorry for my English is not perfect... I open the motor and Change the top bearing, they have some rust and then I cleaning the optical sensors, but the sensors are not dirty. When I reassemble the motor, they fail One or two Times, and then they run perfect on various speeds. I turn off the speed and when I try again the error C34 appear until now. When you say the optical shaft, you refer to the sensors? Thank you for your help.

ReplyDeleteYes, I refer to the sensors (the board with a chip close to the motor shaft). It also says Motor overload in the error message, in your case?

ReplyDeleteYes, the message is motor overload, error C34. I don't have enough room to put the probes and test the sensors with tension on the board. If I remove the sensors, I don't know how to test them out off the board. Do you know the type of sensors and the reference for I buy new ones?

ReplyDeleteI believe you should be able to easily test the sensors on the bench, without these being connected to the actual machine. I'll take a look at mine this weekend to check how you can perform a quick test. The only thing present in the sensor board is a schmitt trigger TTL chip and the two infrared sensors that detect when the encoder teeth pass in front of these. Most likely you should be able to test with just a 5 Volt power supply and a multi-meter. Putting an obstacle in the sensors should cause a shift in the output signals.

ReplyDeleteRegarding the sensor, from what I could find it doesn't seem to be available as a separate part, only as part of the motor..

ReplyDeleteHello, I Will try to test the sensors out off the board.Thank you very much for your help.

ReplyDeleteHI there,

ReplyDeleteI have just done a tear down of my TM5 to repair one of the loose feet and have noticed that my reluctance motor is pretty rusty on the outer metal (not to the coils as far as I can see). Should I leave it or is there a way of removing the rust without compromising the integrity of the coils / motor function.

Hello, the rust is removed well with a dremel and a little sandpaper, in the area of the windings you have to be more careful not to damage the varnish of the coils.

ReplyDeleteHow to upload photos, can you help please.

ReplyDeleteThanks so much for that reply! Worked an absolute treat! The only issue now is when I reassemble, the outer plastic motor shaft ring fits far to tight no matter what I do, causing friction when the motor is on. Any suggestions on how to remedy this? I have tried everything, but each time it clicks into place, it’s way to snug!

ReplyDelete@Tiago, unfortunately it is not possible to upload photos. At most you can add a link to a photo shared elsewhere.

ReplyDeleteCheers

Hello

ReplyDeleteDid you achieve to extract the bearings to replace them? How was the process? The linked video no longer exists.

Does anyone have the specifications of the bearings for this TM31 model?

Thanks in advance

Yes, but I only managed to remove one. I used a combination of persistence, applying some heat, and percussion (hammer) in the areas where the bearing meets the motor chassis. After a bit of effort these will slowly separate. There is quite a solid bond to the motor, via some kind of epoxy.

ReplyDeleteCheers

Thanks for the info. Could you share if possible the dimensions of the bearing? inner/outer shaft diameter and height?

DeleteCiao

ReplyDeleteNecessario un estrattore con gambe modificate (anche con disco radiale da 1mm), lo trovate a buon mercato sul web.

Non importa se c'è del mastice di fissaggio, o se sono presi dal lavoro e dalla temperatura, l'estrattore sposta facilmente il cuscinetto senza danneggiarlo.

Non premere, non fare leva, non colpire, non tagliare, non limare nulla, in quanto c'è il rischio che il rotore non venga calibrato, il che produrrebbe una certa vibrazione che in pochi giorni distruggerà i nuovi cuscinetti .

Un altro problema è vedere quale versione

di cuscinetto da installare, poiché occorre tenere conto di una certa tolleranza all'interno del cuscinetto, con l'obiettivo di facilitarne l'affaticamento nelle fatiche, ad esempio ... impasto del pane a velocità cucchiaio, oppure posizione 1 ... 2 .. . 3 .. 4 .. 5 ... ecc., in modo che

Il nuovo cuscinetto è durevole nel tempo infinito.

Saluti Pol

Hola

ReplyDeleteEs necesario un extractor con patas modificadas (mismamente con radial de disco 1mm), lo puedes encontrar económico en la web.

No importa que exista masilla fijadora, o bien agarrados por su trabajo y temperatura, el extractor desplaza el rodamiento de forma fácil sin dañar.

No presionar, no apalancar, no golpear, no cortar, no limar nada, pues existe riesgo de no quedar calibrado el rotor, lo que produciría cierta vibración que destruirá en pocos días los nuevos rodamientos.

Otro tema es ver que versión

de rodamiento instalar, pues se debe tener en cuenta cierta tolerancia en el interior del rodamiento, con el objetivo de facilitar su fatiga en el trabajo duro, ejemplo ... masa de pan a velocidad cuchara, o posicion 1 ... 2 .. .3 .. 4 .. 5 ... etc., con la finalidad de que

el nuevo rodamiento sea duradero en el tiempo infinito.

Saludos Pol

Hola

ReplyDelete2 unidades

eje-8mm exterior-22mm ancho-7mm

Referencia del rodamiento 608

Debe tener en cuenta que su engrase debe ir protegido en los dos lados por aro a presión, preferible goma plástico.

Saber que el motor trabaja Maximo 10.200 revoluciones, mejor instalar rodamiento de tolerancia intermedia o extra, ejemplo opción,,, C3 es tolerancia extra, fabricado para Alta velocidad y temperatura extrema.

Es fiable instalar buena marca que garantice calidad durante largo tiempo, tanto a velocidad baja como alta.

Para desinstalar debe estar muy bien ajustado el extractor de 2 patas.

La instalación debe ser de forma gradual a presión, con mordaza, prensa, o cualquier sistema que ejerza presión controlada.

Agradezco su lectura

Saludo Pol

.

.

IC at the motor PCB is a ST HCF4093M (quad NAND gate with schmitt trigger inputs). Pin order at the connector is: GND, 5V, Output1, Output2, NTC_sense. I have error 34 in a TM31. The machine was extremely dirty and, to make things worse, cockroaches entered inside motor. I’ve found that one sensor has normal output, alternating between 0V and 4.8V as motor spins, but the other is always at 0V. If I want to go further, I’ll have to open the motor, and I’m not happy doing this.

ReplyDeleteOptical slot sensors are Fairchild MOC70P3. Mine had the detector phototransistor "blind". The IR LED part was OK. I replaced the phototransistor part with one from a similar optical sensor from an old flatbed scanner (Mustek Paragon 1200).

ReplyDeleteGood night know tell me what is the condenser that is next to the current power input fuse my burst and I have no way of knowing

ReplyDeleteCurrently I don't have the board at hand, but will give you the info once I have the opportunity.

ReplyDeleteCheers

Hi

ReplyDeleteI have tm6 with error c370 just after the end of warranty

I’ m an electronic technician ( physics degree)

So I tried to fix myself the error

Changing 3 igbt s under the heat sink and a fuse f 103 on pcb it has worked for some days …but unfortunately a couple of days ago it stopped again with same error

I don’t have schematic

Do you have suggestions ?the capacitors looks good

Thanks for your patience

Simone

Hi

ReplyDeleteI have tm6 with error c370 just after the end of warranty

I’ m an electronic technician ( physics degree)

So I tried to fix myself the error

Changing 3 igbts under the heat sink and a fuse f103 on pcb it has worked for some days …but unfortunately a couple of days ago it stopped again with same error

I don’t have schematic

Do you have suggestions ?

Simone

Hi

ReplyDeleteI have tm6 with error c370 just after the end of warranty

I’ m an electronic technician ( physics degree)

So I tried to fix myself the error

Changing 3 igbts under the heat sink and a fuse f103 on pcb it has worked for some days …but unfortunately a couple of days ago it stopped again with same error

I don’t have schematic

Do you have suggestions ?

Simone

Hi

ReplyDeleteI have tm6 with error c370 just after the end of warranty

I’ m an electronic technician ( physics degree)

So I tried to fix myself the error

Changing 3 igbt s under the heat sink and a fuse f 103 on pcb it has worked for some days …but unfortunately a couple of days ago it stopped again with same error

I don’t have schematic

Hi

ReplyDeleteI have tm6 with error c370 just after the end of warranty

I’ m an electronic technician ( physics degree)

So I tried to fix myself the error

Changing 3 igbt s under the heat sink and a fuse f 103 on pcb it has worked for some days …but unfortunately a couple of days ago it stopped again with same error

I don’t have schematic

@Anonimo regarding your question:

ReplyDelete"Good night know tell me what is the condenser that is next to the current power input fuse my burst and I have no way of knowing"

I am probably a bit late in the game answering it, but the capacitor next to the mains input terminals and the input fuse is a 400 V 22uF electrolytic capacitor.

The board also has a larger electrolytic cap which is rated 400 V 150 uF and sits close to the larger bridge rectifier and IGBTs belonging to the motor speed controller. I presume its main role is to dampen the large transients caused by the switching of the motor coils.